We are a technology-driven manufacturing company specializing in server chassis, various industrial radiators, and mechanical structure solutions. Our services cover precision sheet metal processing, CNC machining, welding, and plastic prototype production.

Our precision laser machining and sheet metal laser cutting services deliver unmatched accuracy. Using advanced lasers, we handle intricate designs with ease, ensuring high - quality cuts for server chassis, industrial heat sinks, and more.

Tubed cold plates are manufactured by using copper tubes firmly

embedded into an aluminum base, adopting riveting skills to improve cooling effectiveness,thermal epoxy is applied to the tube/plate joint to provide a gapless thermal interface between the tube and the cold plate.

Soldering process,combine the reliability of passive two-phase heat transfer with a variety of other thermal management techniques to produce effective, long-lasting cooling solutions.

Thermal Heat sinks

Extrusion process

Skived fin process

Soldering process

Brazing process

All kinds of making process solutions for different power,different fields of application based on customer needs

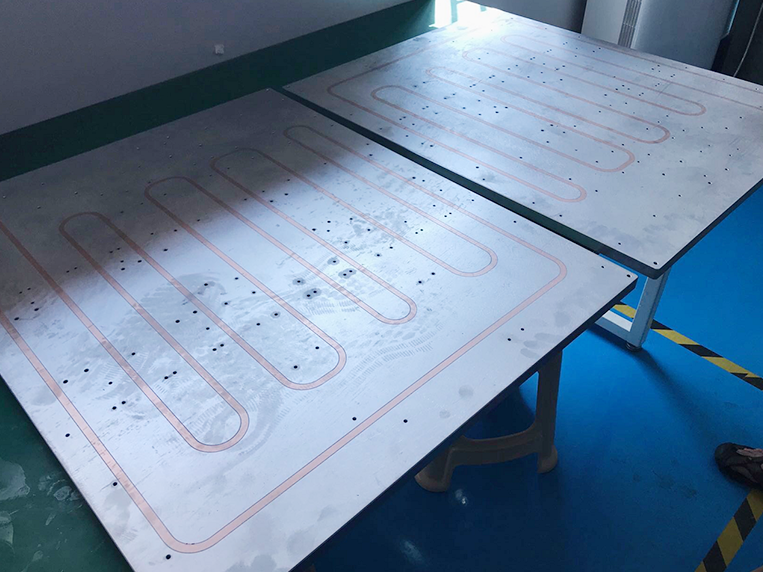

Liquid cold plates

FSW process

Brazing process

Tube plate process

Deep hole drilling

Brazing and FSW Process Liquid cold plate solutions for different fields of application.

CNC Maching

Cutting

Milling

Drilling

Grinding

Specialize in CNC machining, leveraging advanced technology and precise programming

Laser cutting

Cutting carbon steel

Cutting stainless steel

Cutting aluminum alloy

Cutting copper

Employing advanced laser technology, we offer precision laser cutting services, ensuring flawless, accurate cuts for diverse materials.

Thermal Heat sinks

Extrusion process

Skived fin process

Soldering process

Brazing process

All kinds of making process solutions for different power,different fields of application based on customer needs

Liquid cold plates

FSW process

Brazing process

Tube plate process

Deep hole drilling

Brazing and FSW Process Liquid cold plate solutions for different fields of application.

Thermoelectri Coolers

Air to Air

Air to cold plate

Liquid to liquid

Cooling system

Thermoelectric Coolers of the standard module can bring customers an efficient cooling solution

Fan&Thermal pad

Sunon Fans

SanAce Fans

Laird Themal pad

Different specifications fans can meet the different needs of engineers, and can also get brand fans .

Our company specializes in precision CNC machining and laser cutting. At the same time, we also provide cooling solutions for heat sinks and liquid cooling plates, offering highly efficient and tailored solutions to diverse clients.

Dongguan NingTai Precision Machinery Technology Co., Ltd. is located in Shangxia Industrial Zone, Hengli Town, known as the mold capital of Dongguan. With a construction area of 7,000 square meters, it is a technology-oriented production company specializing in server chassis, various industrial cooling solutions, and mechanical structures, covering precision sheet metal, CNC machining, welding, and plastic prototype processes. The products produced include: sheet metal chassis; industrial cooling modules; high-end alloy welded chassis; CNC precision machining of various new energy vehicle parts, medical devices, military components, 5G communication, and automation equipment, among other high-precision parts; various plastic prototypes. The company integrates research and development, manufacturing, sales, and technical services, and has its own import and export rights.

The company boasts a stable team of technical elites, including over 30 engineers with more than 10 years of experience in heat dissipation R&D, senior product engineering, process engineering, and management. They can utilize advanced software for thermal flow analysis, product design, complex processing programming, simulation design validation, and meeting customer JDM requirements.

Currently, the company owns 60 precision machining devices and a team of technicians and skilled workers with over 10 years of experience. They have extensive experience in processing various materials such as aluminum, aluminum-magnesium alloys, copper, stainless steel, as well as special alloys used in aerospace and military applications (such as Invar36 iron-nickel alloy).

The company has passed the ISO9001 quality management system certification and possesses three-dimensional measuring machines, height gauges, projectors, air-tightness testers, thermal resistance testers, and various reliability testing equipment.

FSW process wokshop for cold plate making

FSW process wokshop for cold plate making

Latest News

Stay up to date with the latest product developments, trade shows and other company news from YTThermal

IGBT liquid cold plate for Ifine Infineon IHM-B FZ3600R12HP4

For high-power IGBTs, a s

Application of Thermoelectric Cooling Solution (TEC) in Medical Field

Analytical chemists use r

18650 lithium battery and soft pack battery, which is more suitable for electric vehicles

Modular production of 186

Thermal Simulation Consumption for High Power heat sink Applications

Thermal simulation is an

Research on battery energy storage heat sink technology

At the beginning of this

Research on PCB Heat Sink

For electronic equipment,