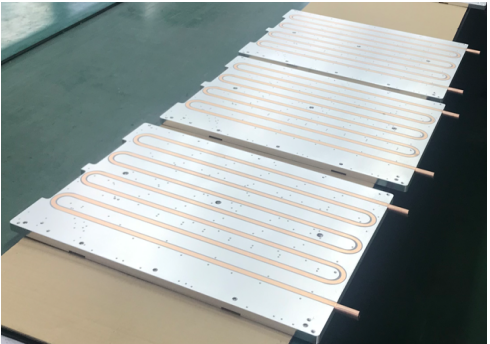

Copper Tube Cold Plates

Customized copper tube cold plates for IGBTcooling.Electronic components in special environments need a heat dissipation solution with low thermal resistance. Usually, this kind of copper tube or stainless steel tube is used as the channel of liquid fluid

Copper tube cold plates solutions

Liquid cold plate

Customized thermal solutions of copper tube cold plates

Our company Hi-Contact technology optimizes the contact area liquid tubes have with a cooling surface to provide the best possible liquid cold plate thermal performance. Our patented geometry used in these designs ensures the most tube-to-plate and tube-to-device contact possible to minimize interface resistance between all contact surfaces. To further increase performance, a thermal epoxy is applied to the tube/plate joint to provide a gap-free thermal interface between the tube and cold plate.

Cold plate material: Al6063/6061/1060 /Copper C1100/Invar36

Copper tube: C1100/Al 1100/Stainless steel

Epoxy bonded material: Thermal conductivity is greater than 3.0 W/(mK)

Finishing: Washing or Chromate coating

Testing: Helium test or water pressure test

Application: IGBT, Laser module

Size:Customized Size

Service:OEM ,cnc machining parts manufacturer

Sample Lead Time:15~20 days

Qaulity Certification:ISO9001:2015

QC control:sampling inspection , full inspection

Surface roughness:0.2 ra

Packaging Detailscartons or as request

Port: HK/Shenzhen

Design Process:

Customer’s input (drawings or asked)-Design proposal-Do the simulation

-Make the prototype-Verification-Customer validation-Tooling fabriacation

-Pre series production-Acceptance Validation-Mass prodcution

Electronic components in special environments need a heat dissipation solution with low thermal resistance. Usually, this kind of copper tube or stainless steel tube is used as the channel of liquid fluid. The way of cooperation makes the copper tube and the aluminum plate closely linked, and there is no thermal resistance medium and gap in the middle. The epoxy resin is cured at room temperature, or the epoxy resin is cured quickly by heating, and then CNC processed. This high-efficiency heat dissipation method Water cooling plates are often used for 5G and Inverter Drive .

Standard specification dimensions are as follows:

(Length X Width X HighX Fin thickness X Fin Spacing,Unit mm)