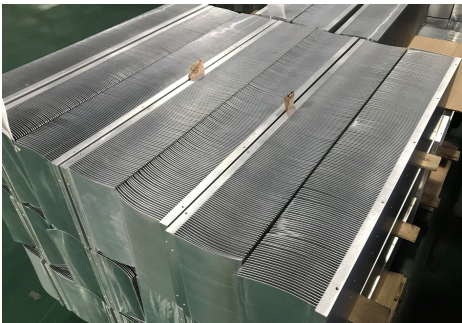

Skived Fin Heat Sink

Custom skived fin heat sink with YT Thermal, in order to meet the needs of customers, we can complete on time according to customers' time, needs, etc. Customized design can meet customer needs

Skived fin heat sink solutions

Heat Sinks

Customized thermal solutions of the skived fin heat sinks. High-density heat dissipation area and customizable size are the biggest advantages of its craftsmanship.

The heat sink of the skived process

It is not limited by the size of the mold, it is a high-efficiency heat sink, it uses the principle of mechanical force, the aluminum plate and the tool form a certain angle, Then under the action of mechanical thrust, the aluminum plate is cut into a thin fin, and then according to the program control, it is piled up one by one, which is very regular.

This regular arrangement forms a heat sink with a large heat dissipation area and high efficiency. For the profile heat sink, the surface of the fin is smooth and the heat dissipation efficiency is low. For the skived fin process, there are rough and uneven points on the surface, it makes the heat sink area larger, which is why the heat sink of the same size, the skived fin heatsink thermal performance is better than the aluminum extruded heat sink. The reason for the high heat dissipation efficiency of the process.

Features and Benefits of Skived Fin Heat Sink

1. The fin size of the heat sink can be processed according to the needs of customers, usually the thickness of 0.05-2.0 can be processed, especially the micro-channel heat sink of the server It is especially suitable for this process, which can increase the exchange area between the water flow and the fin of the heat sink.

2. No expensive mold fee is required, usually only one profile , width and height unit size is required.

3. There is no thermal resistance between the fin and the bottom plate. Unlike the soldering paste soldering process or the epoxy bonded heat sink, there is a relatively large thermal resistance value between the bottom plate and the fin.

Application of Skived Fin Heat sink

1. Large server data center

2. High power inverter, IGBT module

3. Communication equipment

4. LED plant light, heat sink for natural heat dissipation

5. High-power electronic component cooling module

6. High-power laser heat dissipation

Designing specification

Material: Al 1060/1100, Copper 1100

Fin thickness: 0.05-2.0mm

Fin height: less than 125mm

Fin spacing: 6 times the thickness of the fin, such as 1.0mm thickness, the center spacing is 7mm

Bottom plate thickness: 5-25mm, if the thickness is too thin, the flatness of machining will be affected after the hard force is released

The heat sink width: less than 2000mm, it is generally recommended that the high-power heat sink be less than 1000mm

Length of fin: generally less than 700mm

Shortcoming:

The fin processing is done under the action of mechanical force, so as the height of the fin is higher, the fin will become a certain arc shape, but this change is regular and does not affect the heat dissipation performance.

Standard specification dimensions are as follows:

(Length X Width X HighX Fin thickness X Fin Spacing,Unit mm)