Thermoelectric Coolers

Standard Thermoelectric heat sinks and soltuions can shorten cycle time and product reliability for engineer development.

Thermoelectric Coolers

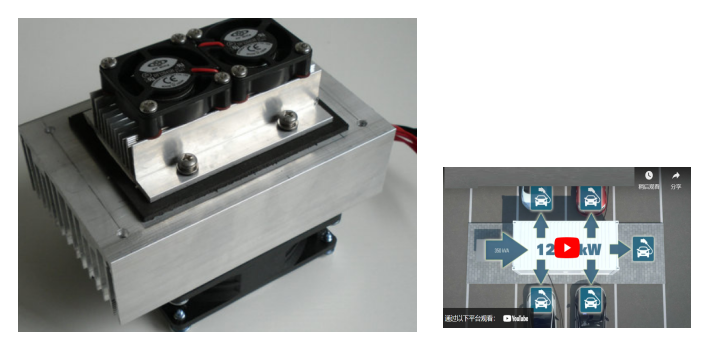

Thermoelectric heat sink of various specifications and powers can be used in different cooling fields

YThermal’s thermoelectric heat sinks offer design engineers a wide range of cooling capabilities, temperature differentials, form factors, finishing options and thermal cycling capabilities. Selecting our standard thermoelectric cooler products enables reduced development time in the design, shortened lead times, and rapid development of custom thermoelectric cooling solutions that match our standard products for the best thermal management solution.

Thermoelectric Refrigeration Technology

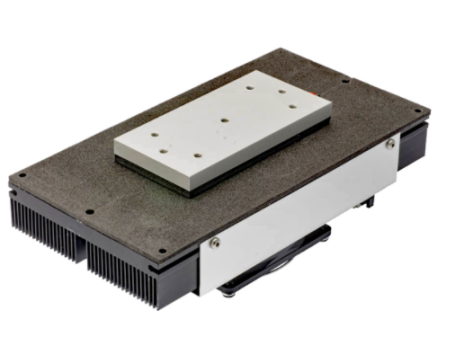

With the development of advanced semiconductor thermocouple materials combined with ceramic substrates, such devices have become commercialized. Thermoelectric coolers are solid state heat pumps that require a heat exchanger to dissipate heat using the Peltier effect. During operation, the DC current of the thermoelectric cooler creates heat conduction and temperature differences across the ceramic substrate, causing one side of the thermoelectric cooler to be cold while the other side is hot. A standard single-stage thermoelectric cooler can achieve temperature differentials of up to 60°C.

Benefits of Thermoelectric Cooling

Thermoelectric coolers have several advantages over other cooling technologies:

Solid-state construction with no moving parts for higher reliability.

Units can be installed in any orientation.

Thermoelectric coolers can cool equipment to temperatures well below ambient. Lower temperatures can be achieved by using multi-stage thermoelectric coolers in a vacuum environment, down to minus 100°C. Thermoelectric devices can be heated and cooled by simply reversing the polarity, which changes the direction of heat transfer. This enables very precise temperature control, up to ±0.01°C can be maintained under steady state conditions.

In heating mode, thermoelectric coolers are more efficient than traditional resistive heaters because they generate heat from the input power source, plus additional heat from the action of the heat pump. These devices are environmentally friendly as they do not use chlorofluorocarbons and have very little electronic noise.

Thermoelectric coolers can be used as energy harvesters, converting waste heat into usable output DC power.

Customer’s input (drawings or asked)-Design proposal-Do the simulation

-Make the prototype-Verification-Customer validation

-Tooling fabriacation -Pre series production-Acceptance Validation-Mass prodcution

Standard specification dimensions are as follows: