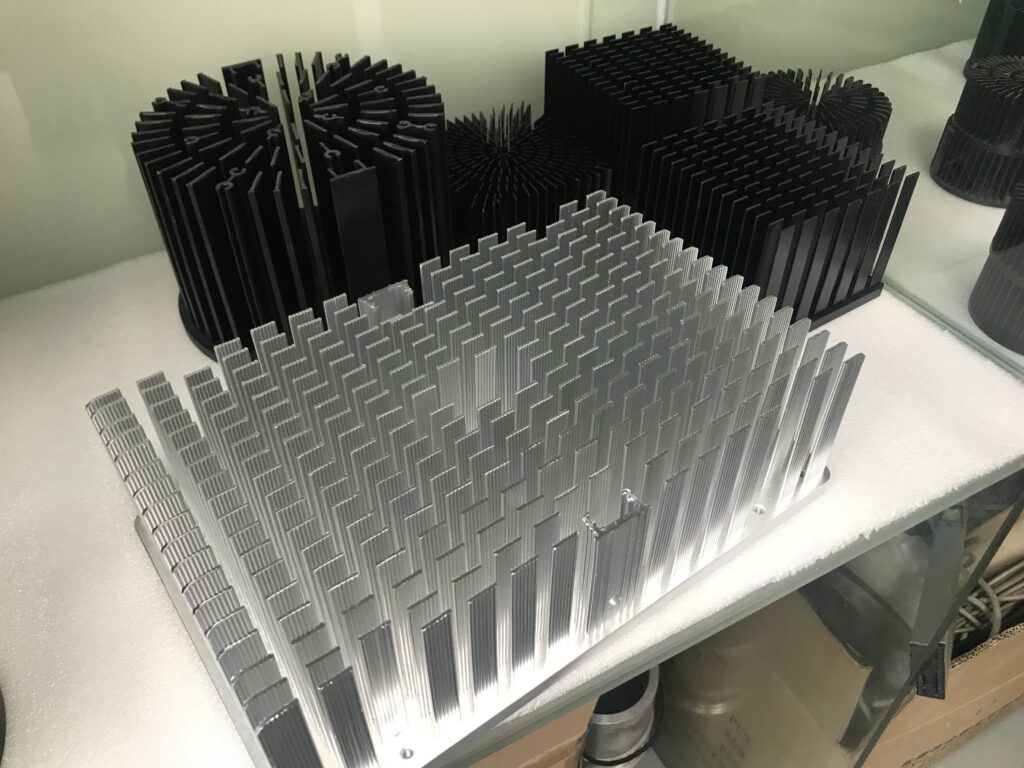

LED Heat sink, Heat dissipation is a major factor affecting the lighting intensity of LED lamps. The heat sink can solve the heat dissipation problem of low illumination LED lamps. A simple stamping process or profile process heat sink cannot solve the heat dissipation problem of LED lamps larger than 100W. In order to achieve the desired illumination intensity and reduce the light attenuation of the LED chips, active cooling techniques must be used to account for the heat released by the LED luminaire assembly. Some active cooling solutions such as fans do not last as long as LED fixtures. In order to provide a practical active cooling solution for high-brightness LED luminaires, the cooling technology must be low energy consumption; suitable for small luminaires; and have a lifespan similar to or longer than the light source.

What is the best way to dissipate heat?

Generally speaking, heat sink can be divided into active cooling and passive cooling according to the way of removing heat from the heat sink. The so-called passive heat dissipation means that the heat of the heat source LED light source is naturally dissipated into the air through the heat sink. In the equipment that is not required, or used to dissipate heat for components that generate little heat, for example, some popular motherboards also adopt passive heat dissipation on the north bridge, and most of them adopt active heat dissipation. Active heat dissipation is forced by cooling devices such as fans. It can take away the heat emitted by the heat sink, which is characterized by high heat dissipation efficiency and small size of the device.

What is active cooling?

In terms of heat dissipation, it can be divided into air cooling, liquid cooling, heat pipe cooling, semiconductor refrigeration, chemical refrigeration and so on.

Air-cooled heat dissipation is the most common heat dissipation method, and it is also a cheaper method in comparison. Air cooling is essentially the use of a fan to take away the heat absorbed by the heat sink. It has the advantages of relatively low price and convenient installation. However, it is highly dependent on the environment. For example, when the temperature rises and overclocking, its cooling performance will be greatly affected.

Liquid-cooled heat dissipation is the forced circulation of liquid to take away the heat of the heat sink under the drive of the pump. Compared with air-cooled, it has the advantages of quietness, stable cooling, and less dependence on the environment. The price of liquid cooling is relatively high, and the installation is relatively troublesome. At the same time, try to install according to the method instructed in the manual to obtain the best heat dissipation effect. For reasons of cost and ease of use, liquid-cooled heat dissipation usually uses water as the heat transfer liquid, so liquid-cooled heat sink are often referred to as water-cooled heat sink.

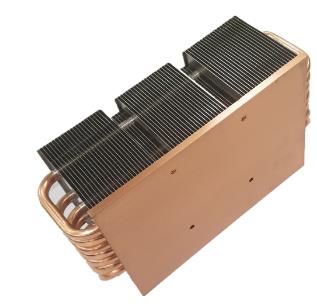

Heat pipe heat sink belongs to a kind of heat transfer element. It makes full use of the principle of heat conduction and the fast heat transfer property of refrigeration medium. It transfers heat through the evaporation and condensation of liquid in the fully enclosed vacuum tube. It has extremely high thermal conductivity and good isothermal performance. The heat transfer area on both sides of the hot and cold sides can be changed arbitrarily, long-distance heat transfer, and temperature can be controlled. Advantage. Its thermal conductivity far exceeds that of any known metal.

Semiconductor refrigeration is to use a special semiconductor refrigeration sheet to generate a temperature difference when it is energized to cool. As long as the heat at the high temperature side can be effectively dissipated, the low temperature side is continuously cooled. A temperature difference is generated on each semiconductor particle, and a refrigerating sheet is made up of dozens of such particles in series, thereby forming a temperature difference between the two surfaces of the refrigerating sheet. Using this temperature difference phenomenon, with air cooling/water cooling to cool the high temperature end, an excellent heat dissipation effect can be obtained. Semiconductor refrigeration has the advantages of low refrigeration temperature and high reliability. The temperature of the cold surface can reach below minus 10°C, but the cost is too high, and it may cause a short circuit due to too low temperature, and the current technology of semiconductor refrigeration is immature and insufficient.

The so-called chemical refrigeration is to use some ultra-low temperature chemicals, and use them to absorb a lot of heat when they melt to reduce the temperature. The use of dry ice and liquid nitrogen is more common in this regard. For example, the use of dry ice can reduce the temperature to below minus 20 °C, and some more “perverted” players use liquid nitrogen to reduce the CPU temperature to below minus 100 °C (theoretically), of course, due to the high price and too short duration, this The method is more common in the laboratory or extreme overclocking enthusiasts.

Generally speaking, ordinary air-cooled heat sink naturally choose metal as the material of the heat sink. For the selected material, it is hoped that it has both high specific heat and high thermal conductivity. It can be seen from the above that silver and copper are the best thermally conductive materials, followed by gold and aluminum. But gold and silver are too expensive, so at present, heat sinks are mainly made of aluminum and copper. In comparison, both copper and aluminum alloys have their own advantages and disadvantages: copper has good thermal conductivity, but it is expensive, difficult to process, heavy, and the heat capacity of copper heat sink is small and easy to oxidize. . On the other hand, pure aluminum is too soft to be used directly. Only aluminum alloys are used to provide sufficient hardness. The advantages of aluminum alloys are low price and light weight, but the thermal conductivity is much worse than that of copper. Therefore, in the development history of heat sink, the following materials have also appeared:

Pure aluminum cold forging heat sink

Pure aluminum heat sink is the most common heat sink in the early days. Its manufacturing process is simple and the cost is low. So far, pure aluminum heat sink still occupies a considerable part of the market. In order to increase the heat dissipation area of its fins, the most commonly used processing method for pure aluminum heat sink is aluminum extrusion technology, and the main indicators for evaluating a pure aluminum heat sink are the thickness of the heat sink base and the Pin-Fin ratio. Pin refers to the height of the fins of the heat sink, and Fin refers to the distance between two adjacent fins. The Pin-Fin ratio is the height of the Pin (excluding the thickness of the base) divided by the Fin. The larger the Pin-Fin ratio, the larger the effective heat dissipation area of the heat sink, and the more advanced the aluminum extrusion technology.

Pure copper cold forging heat sink

The thermal conductivity of copper is 1.69 times that of aluminum, so other things being equal, a pure copper heat sink can take heat away from the heat source faster. However, the texture of copper is a problem. Many advertised “pure copper heat sink” are not really 100% copper. In the list of copper, copper with a copper content of more than 99% is called acid-free copper, and the next grade of copper is Dan copper with a copper content of less than 85%. Most of the pure copper heat sinks on the market currently have a copper content between the two. The copper content of some inferior pure copper heat sink is not even 85%. Although the cost is very low, its thermal conductivity is greatly reduced, which affects the heat dissipation. In addition, copper also has obvious shortcomings, such as high cost, difficult processing, and too much mass of the heat sink, which hinder the application of all-copper heat sinks. The hardness of red copper is not as good as that of aluminum alloy AL6063, and the performance of some mechanical processing (such as grooving) is not as good as that of aluminum; the melting point of copper is much higher than that of aluminum, which is not conducive to extrusion and other problems.

Copper-aluminum soldering process heat sink

After considering the respective shortcomings of copper and aluminum, some high-end heat sink in the market often use copper-aluminum combination manufacturing processes. These heat sinks usually use copper metal bases, while heat sink fins are made of aluminum alloy. Of course, In addition to the copper base, there are also methods such as the use of copper pillars for the heat sink, which is also the same principle. With a high thermal conductivity, the copper bottom surface can quickly absorb the heat released by the CPU; the aluminum fins can be made into the most favorable shape for heat dissipation with the help of complex process means, and provide a large heat storage space and release it quickly. A balance has been found in all aspects.

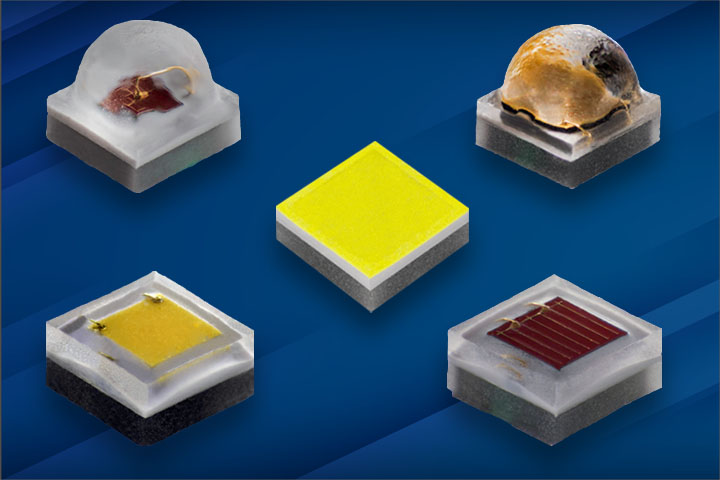

To improve the luminous efficiency and service life of LEDs, solving the problem of heat dissipation of LED products is one of the most important issues at this stage. Therefore, the use of yellow light lithography to make thin-film ceramic heat-dissipating substrates will become one of the important catalysts to promote the continuous improvement of LEDs to high power. At the same time, choosing a good heat dissipation scheme is an important factor to ensure product stability