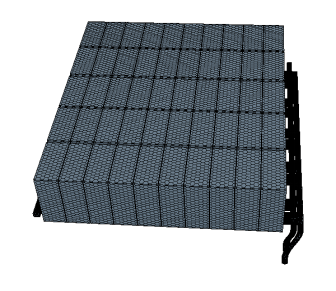

Battery packing cold plate project

Experise

Customized 33W battery packing cold plate case sharing

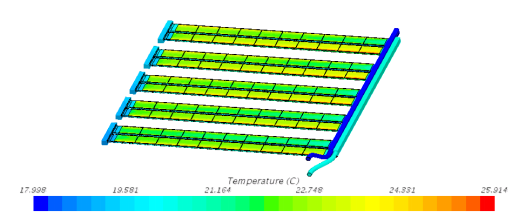

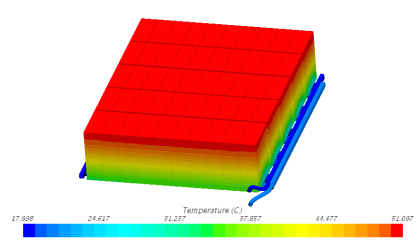

-The ambient temperature is 50℃;

-A thermal pad with a thickness of 1mm and a thermal conductivity of 1.5W/mk is placed between the heat source and the liquid cooling plate;

-A liquid cooling system is used. The coolant inlet temperature was 18°C, and the inlet flow rate was 12.5L/min. The coolant is a 50% ethylene glycol solution. The density is 1077kg/m3, the viscosity is 3.39mPa.s, the specific heat is 3.3KJ/kg.K, and the thermal conductivity is 0.384W/m.K;

-The thermal power consumption of a single cell is 33W, and the thermal conductivity of the cell is: X-9.04W/ m.K, Y-3.56W/m.K, Z-11W/m.K;