IGBT Cooling Solution

There are IGBT cooling solution with various processes, such as Infineon, SEMIKRON and other brands

IGBT Heat sink Solutions

Thermal Solutions for IGBT

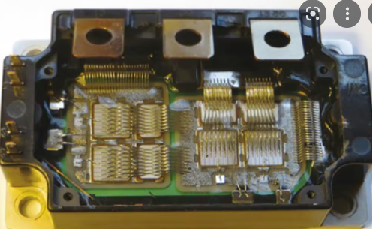

IGBT chips are assembled in discrete plastic packages, called discrete IGBTs, available as single IGBTs and co-packaged with free-drive diodes. The device is suitable for applications such as general purpose inverters, solar inverters, UPS, induction heating, major household appliances, welding and SMPS. The advantages of discrete IGBTs are high current density and low power consumption. Heat sinks using different processes can solve the problem of heat dissipation.

Generally speaking, the greater the power, the greater the heat dissipation area and density of the heat sink. Usually, shovel fins can be used to dissipate heat.

When the power is greater than 2000W, or the space is relatively small, the liquid cold plate solution is needed at this time. Usually, the cold plate has friction stir welding, brazing process welding and copper tube deep buried. As for the process on the aluminum plate, these can meet the heat dissipation requirements of the IGBT. The final solution needs to be comprehensively applied to achieve the optimal solution, thereby producing a higher efficiency heat sink and reducing the overall system cost.

Semikron SKM200GB126D Dual Half Bridge IGBT Module, 260 A 1200 V, 7-Pin SEMITRANS3, Panel Mount

- Skived Fin Heat Sink

- 300W*200L*75H

- 3pcs Heat pipes (D9.5)

Semikron SKM300GB125D Dual Half Bridge IGBT Module, 300 A 1200 V, 7-Pin SEMITRANS3, Panel Mount