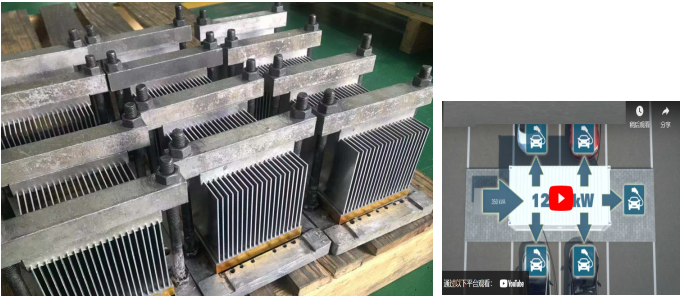

Epoxy Bonded Heat Sink

Epoxy bonding heat sink, this process appeared in the early heat sink process,this process can meet customers' demand for products of any sizes.

Epoxy bonded heat sink solutions

Heat Sinks

Customized Thermal Solutions of the epoxy bonded fin heat sinks

Epoxy bonded heat sink, this process appeared in the early heat sink process, many electronic components do not use this process at present, the main reason is that based on the limitations of skived fin process and patents at that time, few companies can produce heat sink with high fin size and small spacing, while the heat dissipation of chips in the medical industry requires a large area and high density of heat sinks.

In this way, only a base plate can be machined by CNC, the required grooves are opened, and then stamping is used. In the method of mold, the aluminum sheet or copper sheet is punched out to the required shape and thickness, and the fin sheet is put into the groove with a jig, and epoxy resin is applied.

Usually, the 5(w/m.k) thermal conductivity , and then use the oven to bake for 2-3 hours, so that the fin and the bottom plate are tightly connected together to make a high-density heat sink.ed

Material: Al6063/6061/1060 /Copper C1100

CNC machining for the groove

Finishing: Epoxy bonded

Application: Medical electronic heat sinks

Size: Customized Size

Service: OEM, CNC machining parts manufacturer

Sample Lead Time: 15~20 days

Quality Certification: ISO9001:2015

QC Control: sampling inspection, full inspection

Surface Roughness: 0.2 ra

Packaging Detailscartons or as request

Port: HK/Shenzhen

Design Process:

Customer’s input (drawings or asked) – Design proposal – Do the simulation

– Make the prototype – Verification – Customer validation-Tooling fabrication

– Pre series production – Acceptance Validation – Mass production.