Liquid cold plate

Customized YTLCP-F16213620 friction stir welding cold plates for IGBT/Inverter/ Laser module cooling

IGBT’s cold plate and internal water channel use skived fin process to produce micro water channel structure, which is welded by friction stir welding process, it has very efficient heat dissipation performance. CNC precision machining of overall dimensions can meet the heat dissipation requirements of IGBT with different sizes and powers. Designed to fit standard IGBT and other power electronics applications. we can also customize any of the cold plate sizes to fit into your application

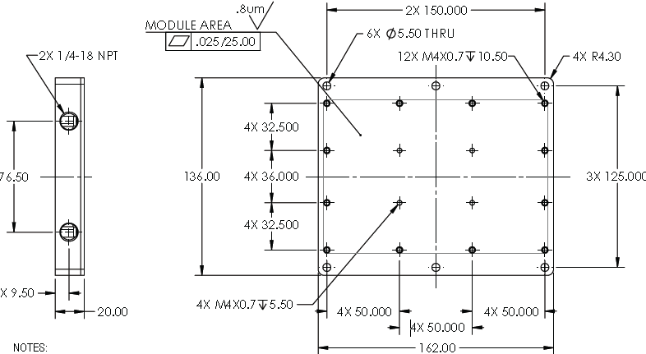

PRODUCT SPECIFICATIONS

Plates Details: Extruded Aluminum 6063-T5

Skived process to make the Micro water channel

Friction stir welding process

Standard Finish: Chromate Coating

High thermal Conductivity

1/4 NPT threaded input and output

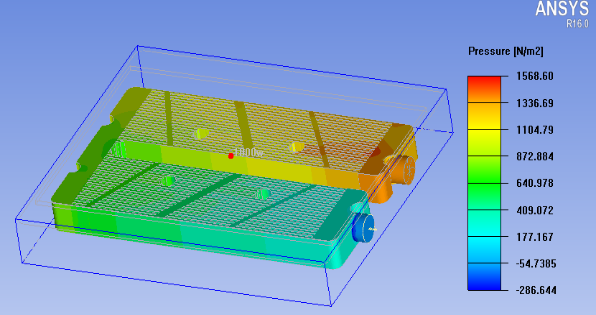

Low pressure drop

Superior heat transfer

Measurement : 162*136*20mm,1.5kg

IGBT COMPATIBILITY

Semikron SemiX® 3

Infineon EconoDUAL™3

Fuji Semiconductor Spring Contact Module

Powered NX™ Series

Other IGBTs or high power devices

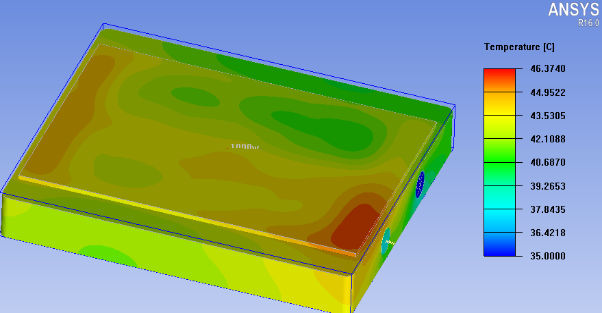

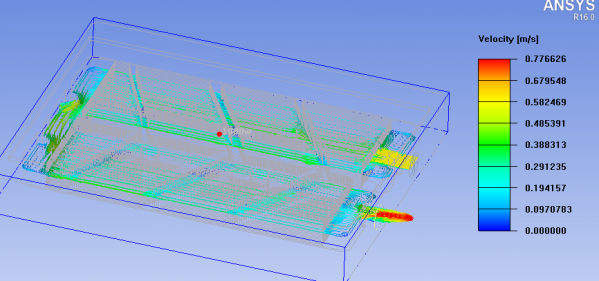

Thermal designing parameters

Thermal power @ 500W

The ambient temperature is 35 °C

The flow of water 4LPM

Thermal resistance: (46.37-35)/500=0.022

THERMAL SIMULATION ANALYSIS